The Horne In-Line Thermal Disinfection Unit, ILTDU, was developed to manage the risk of retrograde contamination of hospital water systems by antibiotic resistant Pseudomonas Aeruginosa (PA) following the tragic and high-profile news in late 2011 and early 2012 of fatal infections affecting premature babies at a major hospital in Belfast.

The hospital water supply was identified as an environmental reservoir of the infectant PA strain. Much research followed, leading to better understanding of retrograde contamination from a hospital ward environment into its domestic water system. PA is now understood to preferentially inhabit pipework biofilm in the last two metres before the terminal fitting (tap or shower) and it’s for this reason that, to be effective, any local thermal disinfection is delivered from a suitable distance upstream of that outlet. At first the preferred solution would be to replace the tap (or shower) fitting, basin and drainage trap. However, a rapid return to positive results for PA contamination was experienced, as it would quickly be seeded from the immediate upstream pipework. Similarly, if thermal disinfection was applied only to the TMV or thermostatic tap fitting – by temporarily increasing its temperature setting to full hot – then this disinfected state merely lasted until the next time the outlet was used.

How is an outlet fitting reseeded with pathogens?

All surfaces in permanent contact with water will develop a biofilm layer. Microorganisms present in the water supply, for example legionella, stenotrophomonas, pseudomonas, will attach to the internal pipe surfaces and grow into a slimy layer, consuming essential nutrients and minerals from the passing water. Biofilms are complex communities highly adapted for survival, and once established, cannot be removed (biofilm growth stage: irreversible attachment). Hans Curt-Fleming, a German scientist specialising in biofilm research, has determined that 95% of the bio-load of a water system is present as biofilm attached to the pipe walls, with the remaining 5% classed as planktonic – i.e., suspended in the water flow. Growth of biofilm continues until the fluid dynamics of the flowing water begin to shear parts off (biofilm stage: detachment and dispersal). Unless effectively managed, and its growth periodically retarded, for example by employing High Velocity (HV) Flushing, then continuous downstream seeding from biolfim pathogens will occur. This kind of flushing, not to be confused with a regular duty flush, allows for significantly higher pipework flow rates compared with normal usage. This effects a change in equilibrium of the fluid dynamics; shearing the excess biofilm from the internal pipe surfaces and removing it to drain. For best effect, to maximise water quality serving any TMV, tap or shower, thermal disinfection should be done in conjunction with high velocity flushing.

So, how does the Horne ILTDU work?

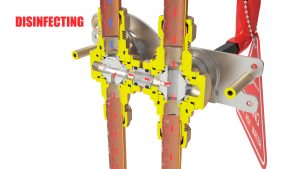

The patented ILTDU is an ingenious but simple device, that utilises two 3-way ball-valves and fits across the hot and cold pipework. It facilitates the temporary rerouting of the hot water supply down the cold-water supply pipe drop to the downstream thermostatic mixing device (thermostatic mixing valve – TMV, thermostatic tap or thermostatic shower valve). Under normal conditions of use, the ILTDU is a passive device, simply allowing passage of hot and cold water through its inlet and outlet ports directly to the downstream tap or showerhead. For the periodic thermal disinfection of the pipework and all downstream fittings, a bespoke key operates the 4-way link mechanism, which transfers the ILTDU from Passive Mode into Disinfecting Mode, changing the pathway of the hot water flow. With the outlet running, system temperature hot water can now enter the mixing device at its cold port. The active component in the mixing device, the thermostatic element, responds to this increase in temperature by expanding further, and pushing the proportioning slide-valve to close tightly over the hot water inlet port, and causing the cold port to open fully. In effect the TMV is tricked into allowing even more hot water to pass through, raising it and all wetting components and downstream fittings, to system temperature. Important Note: The fail-safe [sic] feature of the mixing valve, which shuts the hot supply in event of cold water-supply failure under normal operating conditions does not apply when the ILTDU is in Disinfecting Mode.

It is advised to throttle the flow rate at the outlet to reduce wastage, but the tap outlet or the full shower spray pattern must remain fully immersed in the flow for the duration of the thermal disinfection, or the disinfection will be incomplete. Research into the temperature kill rate for Pseudomonas suggests that a 10-minute duration, at a minimum temperature of 60C, should affect a 6log reduction in Pseudomonas.

Widespread adoption

Since its development in 2015, the ILTDU, as a stand-alone unit and as an integral component of Horne pre-plumbed shower panels, has been widely adopted by NHS and private healthcare providers, as well as FM providers operating in healthcare, and is gaining recognition as the single most effective means for managing retrograde contamination. Alternatives, like point-of-use (POU) water microfilters, address only the symptoms of the problem and, in fact, contribute to further accumulations of biolfim within the outlet fitting and its supply pipework. In addition, POU filters present an on-going consumable cost burden and clinical waste stream. Compared with averaged POU filter costs, the ILTDU can pay for itself in under 6 months and thereafter offer on-going savings and enhanced patient safety. Chemical treatments also represent an on-going cost burden, are generally ineffective in penetrating the biofilm layer and may promote resistance, whilst also negatively impacting the wider environment.

Using the readily available, system temperature, hot water to thermally disinfect the terminal fitting puts little demand on the hot water system. As it is being operated on a small, local scale at the system periphery, there is little risk of affecting total hot water capacity across the wider facility.

Applications beyond healthcare

Beyond acute healthcare, the Horne In-Line Thermal Disinfection Unit also has application for managing the risk of water system contamination in dental and veterinary settings, primary care and mental health, residential care settings and in sporting/club/campsite/leisure amenity showers, especially those that are affected by temporary or seasonal facility shut-downs.

For further information and narrated animation visit http://b.link/Pathogen-Control | 01505 321455